Quality is the key success factor at Hammersen. We are always looking for the best solution, which is why we plan sustainably and according to the latest legal and technical standards. We make the highest demands on ourselves –when it comes to the quality of the projects implemented, the products processed and all services provided, including all processes and procedures.

The basis for this is the high professional qualification of our employees and construction partners, the integration of first-class suppliers and our clearly defined, systematic way of working. For the consistent and permanent implementation of binding rules and standards, our planning and construction processes are guided, documented and continuously improved by a certified quality management system. The management system complies with the DIN EN ISO 9001 standard and is regularly checked and certified by TÜV Nord.

Quality inspection.

A matter of control.

In addition to our internal quality inspection, regular inspections by publicly appointed and sworn experts as well as external monitoring by quality inspectors from the IFBS (International Association for Lightweight Metal Construction) provide evidence of our high quality of execution.

The IFBS quality mark, with which we have been successfully tested and awarded annually since the beginning of the 1990s, confirms the high quality of our construction and assembly services on the one hand, and on the other compliance with the relevant DIN standards, guidelines and the more stringent IFBS quality criteria and technical rules for lightweight metal construction.

Safety.

A question of knowledge.

Safety in your construction project takes top priority for us – as does our responsibility towards our employees, their families and fellow human beings. Occupational safety and health protection are therefore a primary component of our management principles, to which we are committed.

We manage and ensure compliance with and continuous further development of a safe, healthy and performance-enhancing working environment and comprehensive health management, among other things through the AMS BAU occupational health and safety management system. It is regularly tested and certified by BG BAU.

Safety is always a question of the latest state of knowledge too. That is why we attach great importance to the ongoing training and further education of our employees. Through regular information, training courses and further education we promote the skills and the awareness of our employees for safe working in all areas of the company. As a result, for example, all operational employees, site and project managers have an SCC personal certificate.

Research and development.

Our leading edge.

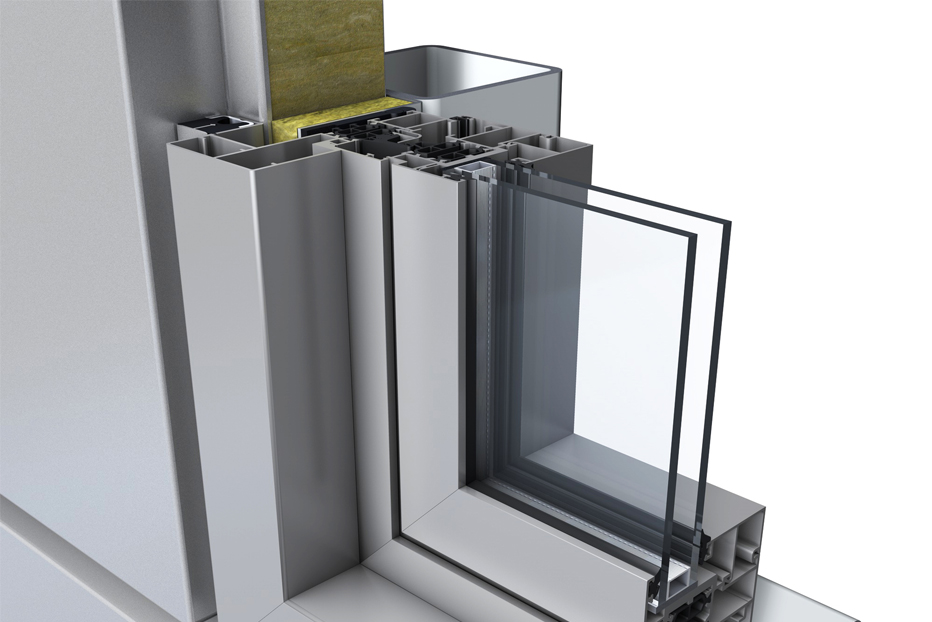

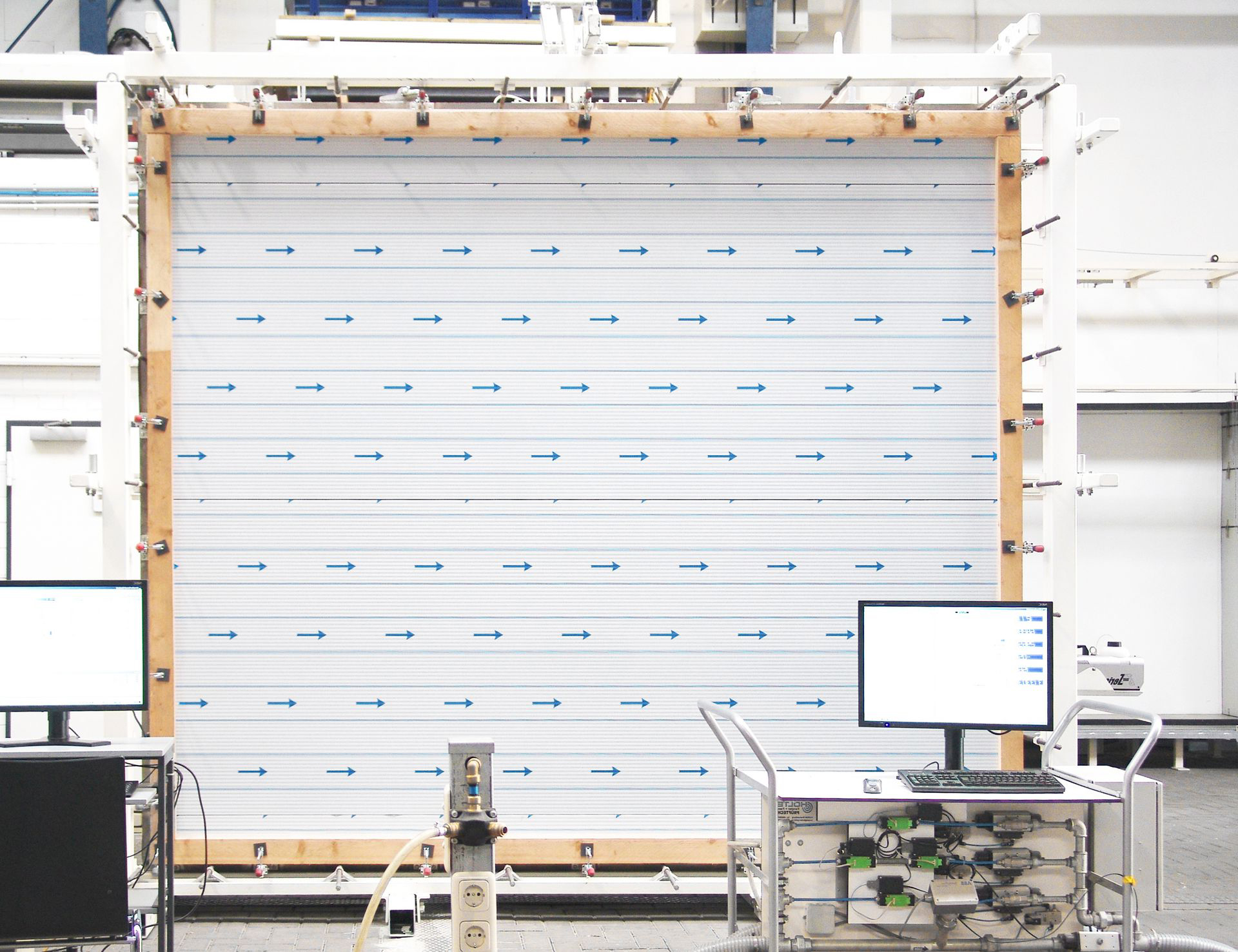

When you talk about the highest quality, this always refers to the current state of research and development. At Hammersen, we determine the development status of our solutions ourselves – through active research.

We are the only private company in the industry to have our own measuring stands for this purpose. Here we can precisely measure the air permeability and driving rain tightness of our roof and facade constructions. Four special measuring stands allow us the highest flexibility when it comes to the overall testing and assessment of windows, doors, gates, facades and building connections.

The experience we gain from this is directly incorporated into the development of our solutions, which thus continue to set new standards in terms of quality, cost-effectiveness and sustainability.

Networks

and cooperations

We are in constant dialogue with experts from trade, science and technology and are involved in numerous trade associations. Hammersen therefore always develops, plans and builds in keeping with the times. As one of the first companies in the IFBS, the International Association for Lightweight Metal Construction, we celebrated our 30th anniversary in 2018.

The long-standing, close cooperation with other experts from the industry and the collaboration in the IFBS working groups offer us and our customers clear advantages: we are always at the cutting edge of technology and safety and develop important norms and quality standards for the industry at the highest level.

Quality assured.

Certified competence.

Clear rules, processes and specifications are important prerequisites for constantly reproducible quality. Their consistent application and continuous improvement determine our success. Anyone who, like Hammersen, feels committed to the highest quality will continue to push their limits and find solutions that set new standards. We have learnt this from over 30 years of experience. This is why our processes and procedures are certified and subject to regular independent checks. In this respect, in many cases our own expectations even go far beyond the standard of certification.